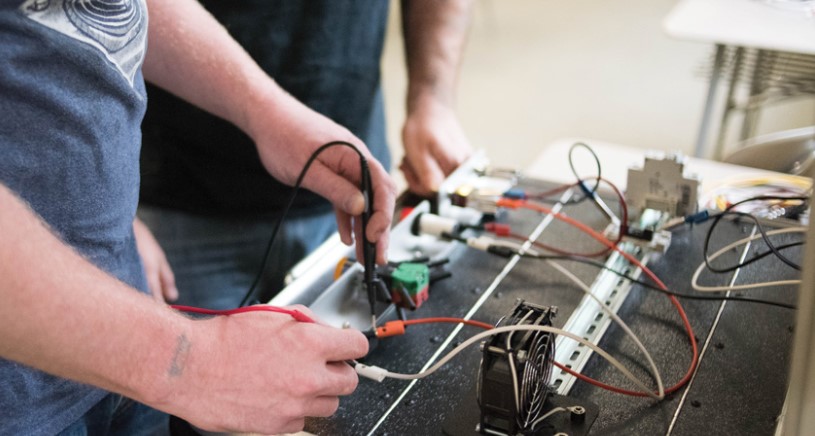

The Electromechanical, Automation & Robotics series of courses offer training in electrical basics, motor regulation, programmable logic controllers, variable frequency drives, pneumatics, sensors, and robotic programming, among other topics, all through the lens of maintenance and problem-solving. Over 50% of class time is hands-on using custom built training consoles, which helps participants develop and retain practical skills that are essential for addressing the challenges encountered in industrial environments.

The EAR courses are short-term and designed to upskill and reskill your current workforce without missing too much time at work.

July-December 2025

July-December 2025

- Electrical Fundamentals

- Electrical Troubleshooting

- Advanced Rockwell RS5000 PLC

- Basic Rockwell RS500 PLC

- Basic Rockwell RS5000 PLC

- Electrical Fundamentals

- Electrical Troubleshooting

- Industrial Electro-Pneumatics

- Industrial Instrumentation & Control

- Introduction to PLCs

- Motor Control & Relay Logic

- National Electrical Code Review

- Variable Frequency Drives